Investment Casting

How 3D Printing and Filaments Are Enhancing Investment Casting Processes

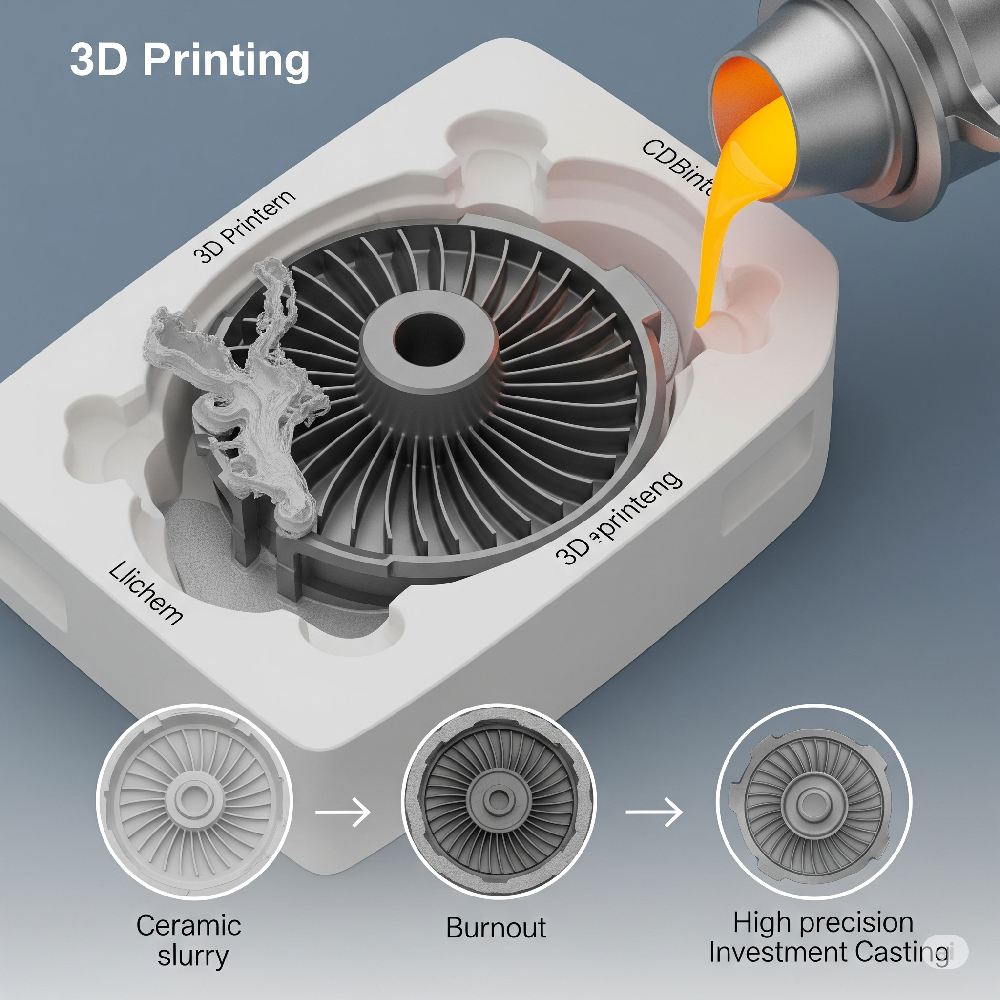

Investment casting, also known as lost-wax casting, is a time-tested manufacturing method known for producing complex, high-precision parts. Traditionally, this process involves creating wax patterns, which are used to form ceramic molds for metal casting. But today, 3D printing is revolutionizing investment casting by streamlining the pattern-making stage—thanks to advanced 3D printer filaments designed for burnout and dimensional stability.

With the right materials and printing techniques, manufacturers can skip the tooling phase, cut lead times, and reduce costs—all while maintaining the accuracy and finish investment casting is known for.

1. How 3D Printing is Used in Investment Casting

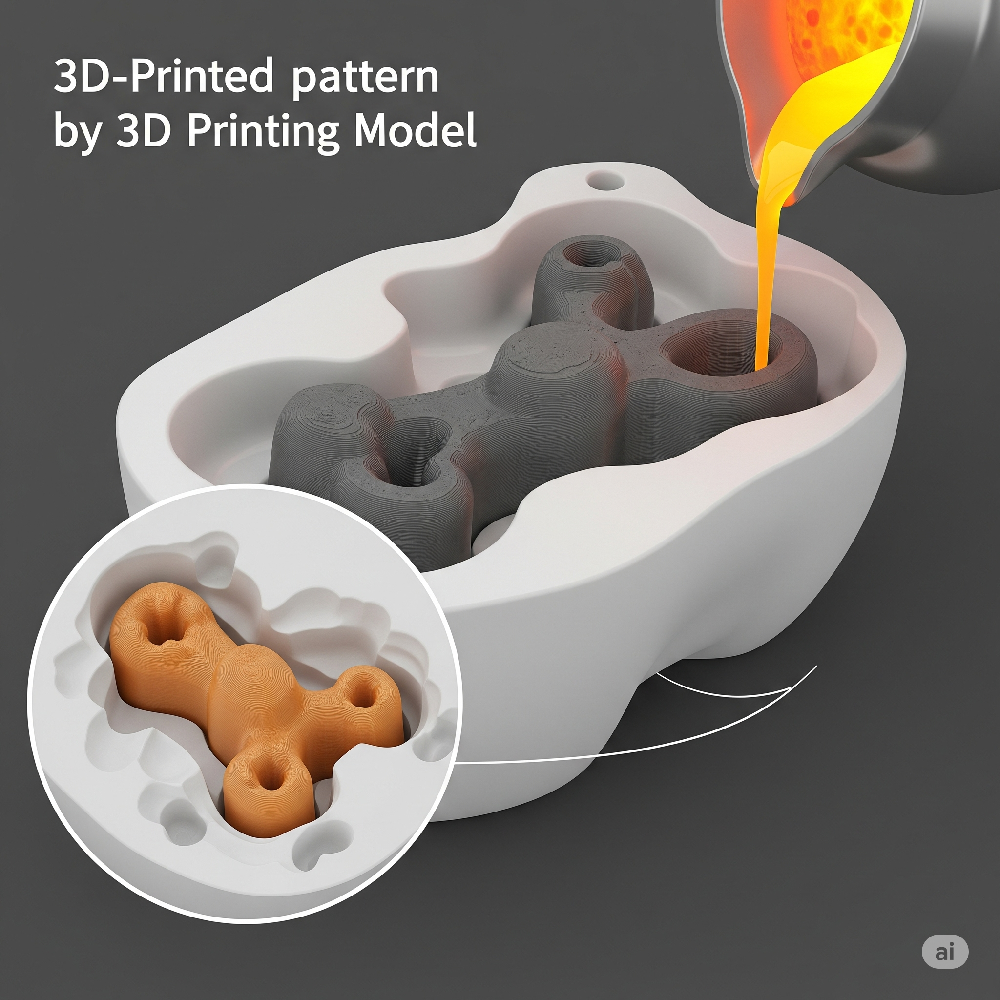

The integration of 3D printing into investment casting typically replaces the wax pattern stage with a digitally produced model, often made from burnout-friendly filament. Key applications include:

- Pattern Creation: Instead of machining or molding wax, foundries can print highly detailed patterns directly from a CAD model.

- Tool-Free Prototyping: Engineers can validate designs without committing to expensive tooling.

- Low-Volume Production: Ideal for custom or limited-run castings where tooling would be inefficient.

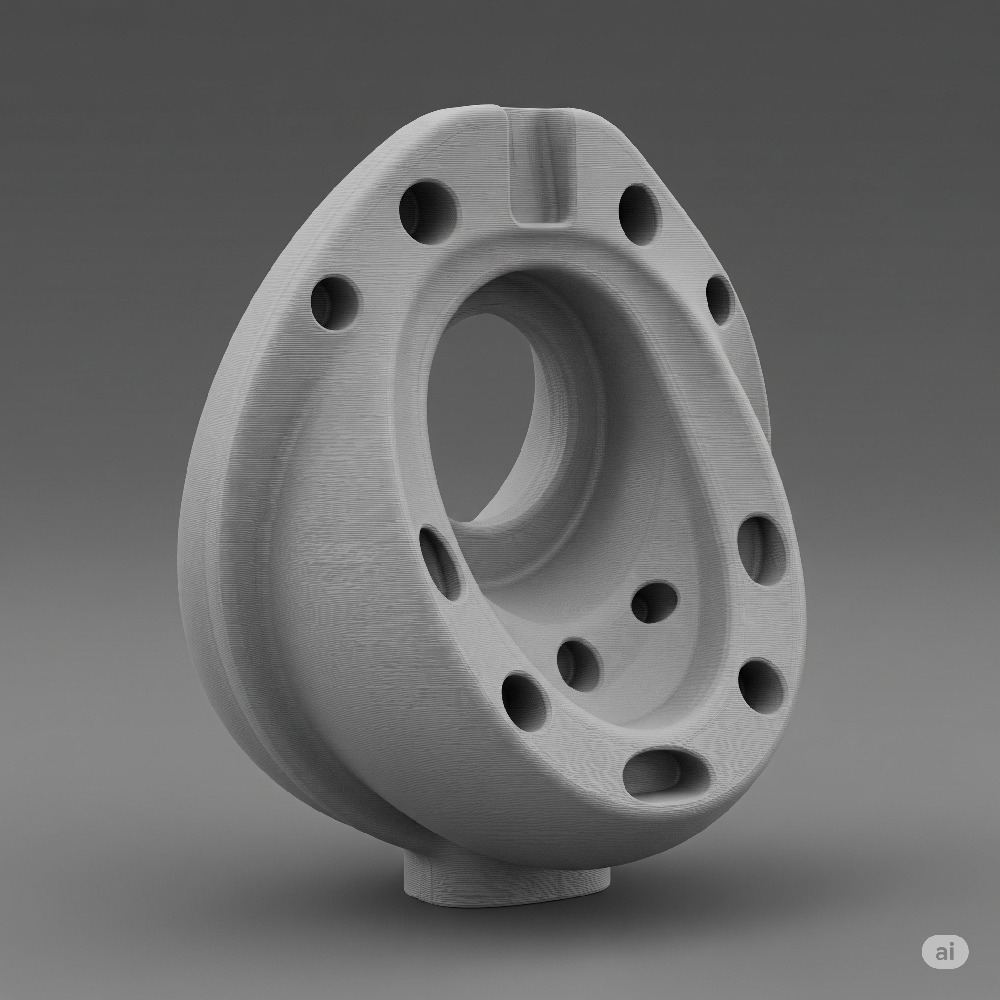

- Complex Geometries:Design freedom offered by 3D printing allows for intricate internal features, thin walls, or undercuts that are difficult with traditional methods.

By replacing traditional wax with 3D printed patterns, foundries can dramatically reduce the time and effort needed to go from concept to final cast.

2. Best 3D Printer Filaments for Investment Casting

Not all filaments are suitable for use in investment casting. To ensure a clean burnout without ash residue or deformation, specialized casting-grade 3D printer filaments are required. Commonly used filaments in investment casting include:

- PLA (Polylactic Acid): A widely used filament for casting patterns due to its low-cost, good print detail, and relatively clean burnout.

- Castable Wax Filaments: Formulated to mimic traditional wax patterns, these filaments burn out almost completely with minimal residue.

- Polystyrene-Based Filaments:Known for extremely clean burnout behavior, used in aerospace and medical-grade casting.

- PVA (Polyvinyl Alcohol): Can be used as a support or sacrificial core material in complex mold setups due to its solubility in water.

Using a burnout-optimized 3D filament ensures a cleaner casting process, better mold integrity, and higher final part quality.

3. Benefits of Using 3D Printing in Investment Casting

- Eliminates Tooling Costs:Patterns can be printed directly, removing the need for expensive and time-consuming molds.

- Faster Lead Times: Go from CAD to cast part in days, not weeks.

- High Accuracy and Surface Detail: Modern 3D printers and filaments allow for fine surface finishes and tight tolerances.

- Design Flexibility: Easily produce complex or one-off designs that are impossible with traditional wax carving or molding.

- Reduced Waste:Additive manufacturing minimizes material usage during the pattern creation phase.

These advantages make 3D printer filament applications in investment casting a game-changer for industries like aerospace, automotive, jewelry, and medical.

4. Industries Benefiting from 3D Printed Casting Patterns

- Aerospace:Lightweight turbine components and high-performance parts.

- Jewelry:Intricate, one-of-a-kind designs with fine detailing.

- Automotive: Prototyping and limited runs of high-performance parts.

- Medical: Custom orthopedic implants or surgical instruments with unique geometries.

Each of these industries leverages filament-based 3D printing to improve flexibility, reduce costs, and speed up production cycles without sacrificing quality.

5. Preparing 3D Printed Patterns for Casting

While the printing process is relatively straightforward, proper post-processing and burnout preparation are key:

- Drying:Ensure the pattern is thoroughly dried to avoid defects during burnout.

- Surface Smoothing:Use chemical or mechanical methods to achieve smoother surface finishes if needed.

- Controlled Burnout Cycles: Follow a carefully calibrated burnout schedule to avoid residue and maintain mold integrity.

Selecting the right casting filament and following proper procedures ensures success in high-precision casting projects.

Conclusion: Unlock Precision and Speed in Investment Casting with 3D Printer Filaments

From faster prototyping to complex custom components, 3D printing and specialized filaments are transforming investment casting. By eliminating tooling and enabling rapid, precise pattern creation, this digital approach is becoming an essential tool for modern foundries. Discover our range of burnout-optimized 3D printer filaments and see how you can modernize your casting workflow today.