Automotive

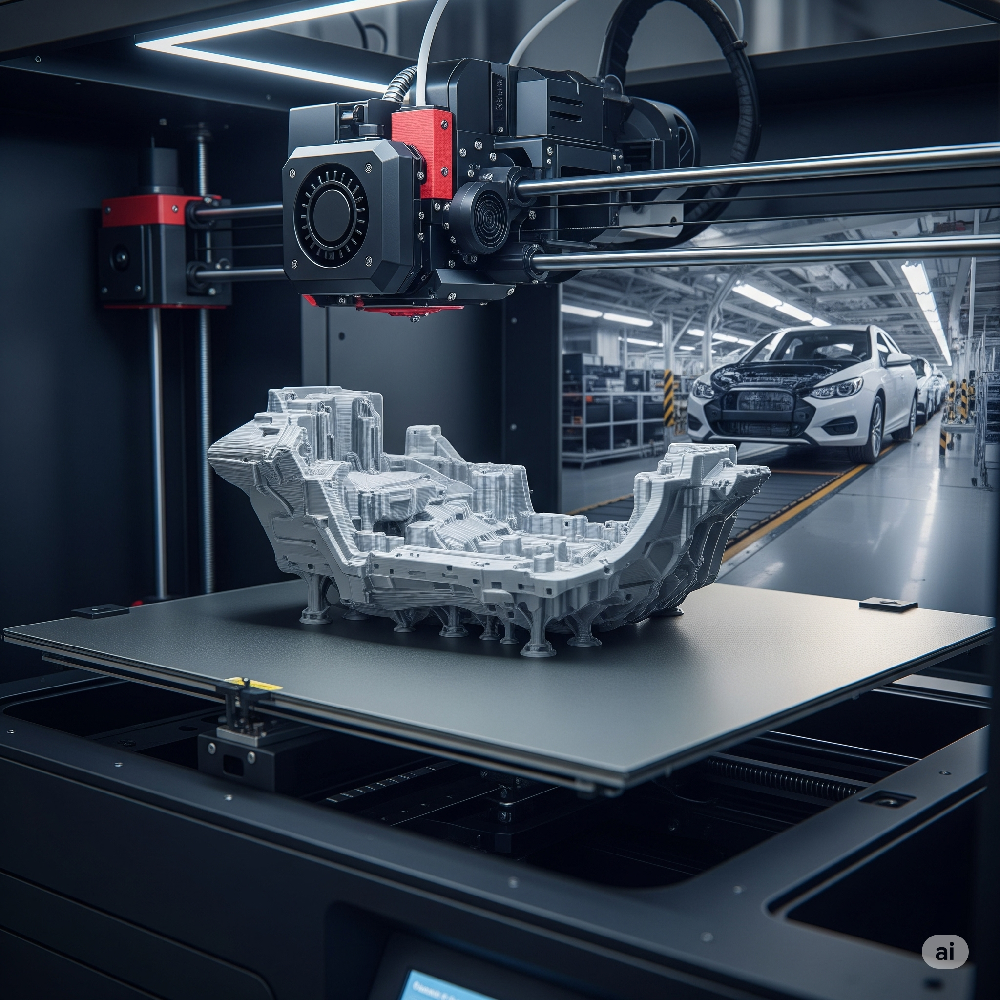

Driving Innovation: 3D Printing and Filaments in the Automotive Industry

The automotive industry is steering toward a future defined by speed, precision, and customization. At the heart of this transformation is 3D printing, or additive manufacturing, powered by a diverse range of 3D printer filaments. From rapid prototyping to end-use components, 3D printing filament technology is helping OEMs, suppliers, and custom shops accelerate development cycles, reduce costs, and push the boundaries of vehicle design.

1. Rapid Prototyping and Concept Validation

Before a new vehicle sees the light of day, designers and engineers must iterate countless concepts:

- Scale Models & Concept Parts:Print exterior panels, interior trim pieces, or small-scale chassis sections to evaluate form and ergonomics.

- Fit-and-Function Testing: Produce quick-turn fixtures and mating components to verify tolerances and assembly sequences.

- Customer Demos: Showrooms and roadshows benefit from realistic, 3D-printed mockups that engage stakeholders and end customers.

By using low-cost, high-detail filaments like PLA and PETG, teams can go from CAD to physical model in hours—dramatically compressing the design loop.

2. Tooling, Jigs, and Fixtures on Demand

Efficient production lines rely on precise tooling:

- Assembly Fixtures:Custom-fit jigs that hold body panels, wiring harnesses, or subassemblies in exact alignment.

- Inspection Gauges: Go/no-go gauges and measurement aids ensure every part meets spec.

- Maintenance Aids:Specialized holding fixtures and service tools reduce downtime during vehicle servicing.

Durable, engineering-grade filaments such as Nylon, ABS, and Carbon Fiber–reinforced blends deliver the strength and wear resistance needed for shop-floor use.

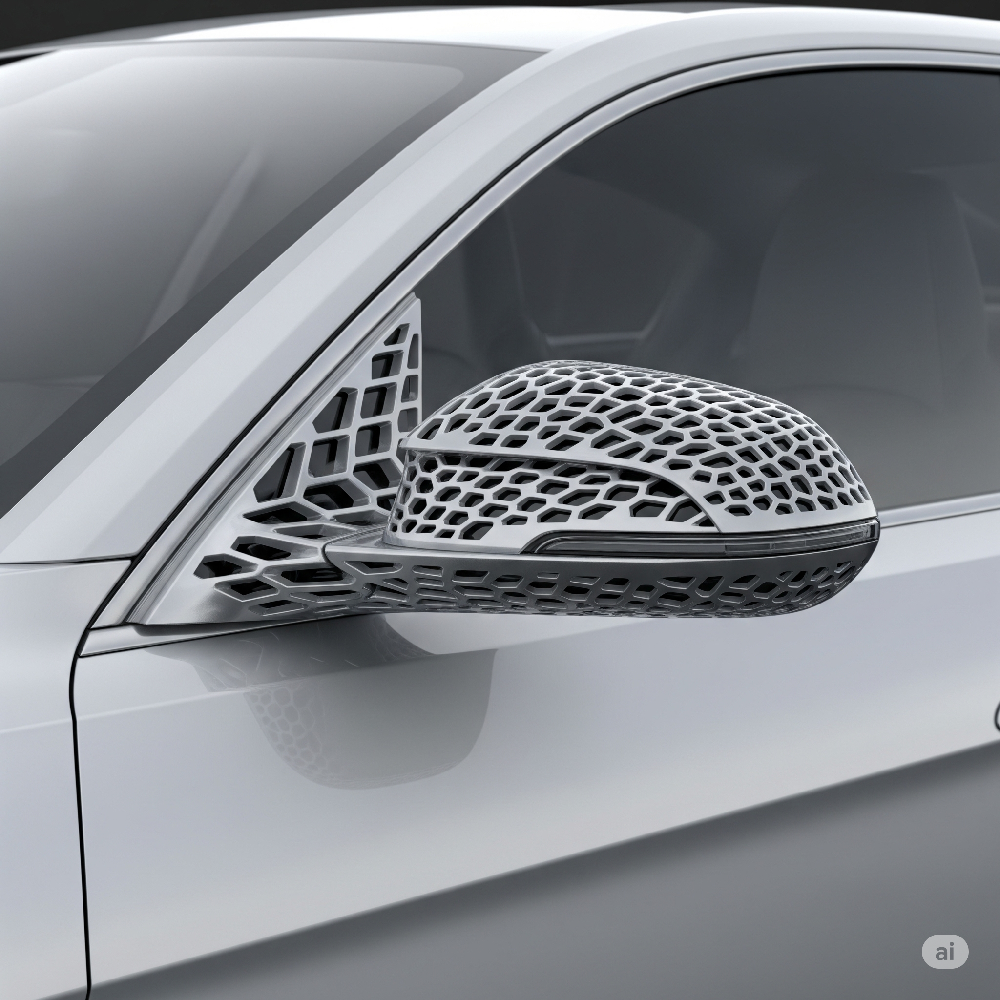

3. Low-Volume and Custom End-Use Parts

Mass-production isn’t the only game in town:

- Aftermarket Components: Custom grilles, badges, trim pieces, and even body panels for limited-edition vehicles.

- Replacement Parts:Hard-to-find clips, brackets, or housings can be printed on demand, closing the gap when legacy parts are discontinued.

- Specialty Performance Parts:Lightweight brackets, ducting, or sensor mounts printed in high-temperature filaments like Polycarbonate or PEEK.

With 3D printing filament options spanning flexible TPU to high-strength composites, small-batch runs become economically viable.

4. Weight Reduction and Complex Geometries

Fuel efficiency and performance demand lightweight structures:

- Lattice Structures & Topology Optimization:Create strong yet lightweight parts with internal lattices impossible to machine conventionally.

- Integrated Functionality:Combine multiple components into a single printed assembly, reducing fasteners and part count.

- Lightweight Brackets & Supports:Carbon fiber–filled filaments offer superb stiffness-to-weight ratios for non-structural parts.

Additive manufacturing’s freedom of design helps engineers shave pounds—translating directly to better fuel economy or range in electric vehicles.

5. Key Benefits of 3D Printing in Automotive

- Accelerated Development:Prototype parts in hours, not weeks.

- Cost Savings:Avoid expensive tooling for short runs or custom projects.

- Supply Chain Resilience: Print spare components on-site, mitigating stock shortages.

- Design Freedom:Produce highly complex shapes, undercuts, and internal channels.

- Sustainability:Minimize waste with additive processes; many filaments are recyclable or bio-based.

These advantages empower automakers to respond rapidly to market trends and regulatory pressures.

6. Future Trends

The intersection of 3D printing, advanced filaments, and digital design is only growing stronger:

- Metal Filament Printing: Metal-infused polymers for sinterable parts, bridging the gap to full metal additive.

- Multi-Material Printing: Combines rigid and flexible filaments in a single build for hinge-integrated or overmolded parts.

- High-Performance Polymers: Wider adoption of flame-retardant, UV-stable, and chemically resistant filaments suited for under-hood and exterior applications.

- On-Vehicle Printing: Mobile printing units at service centers for immediate part replacement.

As automotive moves toward autonomy, electrification, and personalization, 3D printing filament technology will be a critical enabler of innovation.

Conclusion: Shift Gears with 3D Printing Filaments

For manufacturers, tier-one suppliers, and custom shops alike, integrating 3D printing and the right 3D printer filament is a strategic necessity. From agnostic prototyping to robust end-use components, additive manufacturing is revolutionizing how vehicles are designed, built, and maintained. Ready to accelerate your automotive projects? [Explore our range of industry-grade 3D printer filaments designed for the rigorous demands of the automotive sector.]